How might we make grass-fed beef farming more sustainable and less wasteful?

Through a new circular model for egg production.

RESEARCH, BRAND INNOVATION, STRATEGY, VISUAL DESIGN & BRAND IDENTITY, SERVICE DESIGN, PRODUCT DESIGN

PROJECT OVERVIEW

CHKN co-op is a brand and circular model for raising chickens with cattle on pasture land. This was an independent project completed in my 3rd semester of grad school that was inspired by my love of raising chickens, sustainable farming practices, and creating a cleaner planet.

MY ROLE

I conducted qualitative/quantitative research and interviews, designed and modeled a suite of innovative products, designed and tested the UX/UI experience, while creating a powerful brand and narrative that brings CHKN to life—showcasing how the brand would exist in the world.

INTRODUCTION

Life on a farm was a fun and educational experience for a young boy with an innate fascination with animals and getting his hands dirty.

Since shoveling chicken and horse manure on my family’s farm, I’ve always known animal waste was a smelly, yet powerful substance. There’s a reason my grandparents called it “Black Gold”. However, in order to get all of the benefits one must be intentional about using it.

PROBLEM

In America, food animals produce 2 billion tons of waste in the form of manure each year.

Interestingly enough, only 335 million dry tons of waste come from animals at large-scale feeding operations; meaning a lot of this waste exists on smaller farms around the country—like my family's farm. Yet, it is seen as a useless waste product. Through further research, I found cattle produce significantly larger amounts of waste volume per weight than any other farmed animal.

REALIZATION

I thought if we can fix the waste problem on these small farms; we can in turn fix the problem on a larger scale.

When I realized cattle farming was a huge part of the waste problem, I began thinking about alternative ways to farm and what my grandparents taught me about the magic of manure. The very reason for the problem actually held the key to the solution. We just need to reimagine how farmers use land and reposition waste as a valuable asset—rather than a useless byproduct.

90% of all cattle farms

in the US are small-scale.

(USDA, 2014)

OPPORTUNITY

We have the potential to create a network of agricultural ecosystems that not only repurposes waste but also increases land efficiency and income for small-scale farmers.

Studies show that rotating chickens with cattle has many benefits: it stimulates regrowth and deeper roots, increases rainwater retention, and the soil’s capacity to sequester atmospheric carbon. This process results in balanced, organic fertilizer (in the form of manure) that is evenly distributed across the land—year after year farmers will see healthier soil and greener pastures.

This is the industrial farming model where farmers practice monoculture—raising only one type of animal on the land. It is inherently wasteful, along each step of the process waste is produced. As you can see the waste in the industrial model is repurposed in the circular model.

My solution focuses on eliminating these 6 by-products of monoculture, with a new circular farming model which harnesses the benefits of polyculture—a rotational farming practice, where multiple species of animals are staggered and frequently moved across the land.

.png)

SOLUTION

CHKN is a co-operative that is reimagining chicken farming.

CHKN stands for something greater than its final product: eggs. We’ve thought about the totality of the farming system and how each step in the process influences the next. The co-operative business model has been designed to be a recursive loop.

This model harnesses the ripple effect of small actions to create significant environmental change on a larger scale. Each member of the co-op has a crucial role to play.

As farmers and consumers, we are stronger in numbers—together. Join the Flock.

THE FARMER

Partner farmers are supplied with a suite of cutting-edge products that allow them to raise chickens along with their cows with minimal effort and maximum results. Our service eliminates the need for fertilizer and other inputs—saving costs, machinery time, and prevents runoff of commercial chemicals. In turn, the farmer will also accrue supplementary income from eggs sold through the business model.

THE CONSUMER

CHKN | co•op offers a zero-waste subscription egg service to consumers that are interested in being a part of the co-operative. The service is centered around the well-being of the animals, the quality of the eggs, reusable packaging, and transparency between the consumer and the brand.

THE JOURNEY

From cow to chicken to farmer to consumer and back again

This is an overview of the process: from how a new partner farmer would get started to the eggs ending up with the end consumer. The journey showcases how CHKN manifests itself in each of the user's lives, adds value on a daily, monthly, and yearly basis, and reduces friction during the process of producing and selling eggs.

1

GETTING STARTED

Outside of Richmond, in Goochland County, A CHKN rep works with a local farmer to survey his land with GPS and calculates how many chickens can be rotated on his pasture land. CHKN works closely with the farmer educating them on proper rotational grazing techniques—if they aren’t already familiar. A few weeks later, the smart coops are delivered along with laying hens.

2

ROTATIONAL SET-UP

.png)

The CHKN rep helps the farmer get started with the process by programming the coops to move across the farmer's pastures based on the primary data that was collected. Once the coops are set-up, the chickens and the coops are rotated a few days behind the farmer’s cattle.

3

CHECKING IN VIA THE DASHBOARD

.png)

Throughout the week the farmer and CHKN rep can use the CHKN app to monitor the coops and chickens. Here, you can see the user can select a particular coop to check on feed, water, and battery levels from solar energy. This is accessed through the Location/Tracking tab.

4

EGG COLLECTION & ANALYTICS

The next day the farmer goes out to do his daily egg collection, while he tends to the cattle. These roll-out laying boxes have a sensor that counts the eggs as they roll out into the collection channel. He can see how many eggs have been laid on any given day. He can also compare income and egg productivity, week after week, month after month, and year after year.

5

SUPPLY REPLENISHMENT & ANALYTICS

The farmer remembered to bring along feed and water in his truck to replenish the supplies that are running low in the Coops. Afterward, he can look at charts that compare feed and water consumption by year, month, and week. This feature will help him plan for the future and calculate his farming finances.

6

EGG CRATE STORAGE

The eggs the farmer collected from the coops are stored in the modular egg cartons that fit snugly into transport crates. They are kept on the farm until they are ready to be picked up by the CHKN delivery person.

7

EGG TRANSPORT TO CONSUMERS

The delivery person picks up the eggs early Saturday morning from the farm and brings them to the farmers market for pick-up or delivers directly to the consumer after the farmer’s market for an extra fee.

.png)

8

CONSUMER PICK-UP AND ENJOYMENT

At pick-up, the consumer returns their old egg carton bottom and picks up their new carton of eggs from the farmers market. They take their eggs home to enjoy them throughout the week. The delivery person returns the empty carton bottoms to the farmer to begin the process all over again.

BACKGROUND

From farm boy to college student to experience designer

A boy with a passion for entrepreneurship.

At the tender age of thirteen, I started raising a flock of 50 chickens for egg production. I designed and created egg cartons, business cards, and a logo for my business. I even taught myself Google SketchUp, so I could 3D render my chicken coop and tractor designs. My dad and I worked together to convert the old shed on our property into a functional chicken coop.

A college student with a passion for local food and sustainability.

In college, I was part of a student-run CSA and this is when my love for farming and sustainability became intertwined. I began reading many books about sustainability and regenerative farming practices like “The Omnivore's Dilemma” and “Folks This Ain’t Normal”. I even got to meet and talk to Joel Salatin at the premiere of the documentary “Polyfaces” at the Virginia Film Festival.

An experience designer looking to rethink farming to solve a problem.

Fast forward to my 3rd semester of graduate school, it has all come full circle. I chose to use my independent study to continue my exploration of regenerative agriculture and tap into a big environmental problem that needed to be solved.

DESIGN PROCESS

How I designed and why I made certain design choices.

RESEARCH

FUELED BY LOTS OF YOLKS: FRIED, SCRAMBLED, AND POACHED

Through research, competitive brand analysis, and quality/price comparisons—I found that the vast majority of brands that offer free-range or pasture-raised eggs charge a premium for the product. I priced my subscription model to not only incentivize consumers to sign-up for a full season but also as a more affordable option than other brands on the market.

.png)

The brand will launch itself in Virginia. Specifically, in Richmond, Charlottesville, and Northern Virginia. These locations were strategically chosen for a number of reasons:

The brand will launch itself in Virginia. Specifically, in Richmond, Charlottesville, and Northern Virginia. These locations were strategically chosen for a number of reasons:

1: The cities' proximity to local small-scale cattle farms and thriving local food scenes—the product doesn’t have to move very far.

2: The consumers are already familiar with the farms from their local farmer's markets—they can trust the source.

3: Due to the size of the cities: subscription members can easily pick up their eggs at their cities’ farmers market.

CATTLE FARMER PAINPOINTS

They have to rely partially on off-farm income to support the household.

They struggle to compete with large-scale industrial beef corporations.

On average farmers can only devote 28.9%—47.3% of their time to operations and upkeep.

Smaller farms makeup 90.4% of all farms with cattle, but only hold 45.9% of the market.

The price and upkeep of pasture land keeps rising each year.

In the 1960s the land price to product ratio was 1:1, currently, it is 20:1—a 1,900% increase.

Key Insights: The farmer's time and money are paramount. Smaller farms would benefit from a cooperative business model in order to compete with larger corporations. Farmers must increase their land efficiency by changing the way they farm to increase their profit margin. Lastly, the solution had to be integrated into farmers' routines, because of their busy schedules.

SERVICE DESIGN

The brand's service was designed by taking into consideration the user needs of each individual in the cooperative and how each member interacts with one another over the course of a business week—whether it is a direct or indirect interaction. Each week the process starts over again.

.png)

AUTONOMOUS SHELTER DESIGN

The smart chicken coops were designed to hold 200 laying hens each. The 8' x 16' dimensions are the optimal size for easy movement and enough room to house the hens at night and to lay eggs. Egg production is monitored by the roll-out laying boxes. Food and water consumption is tracked by automatic dispensers. The roosts retract during the day and descend at dusk.

PRODUCT PACKAGING DESIGN

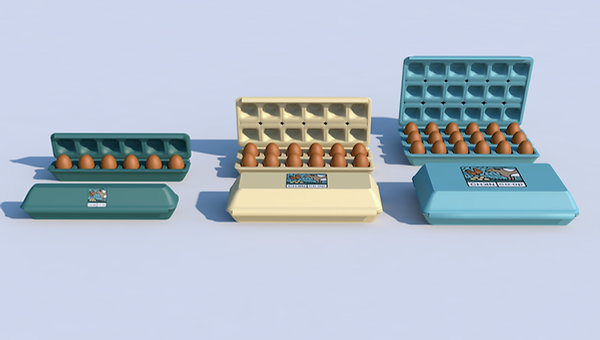

Single-use egg cartons are a huge source of waste in the United States—that's why I wanted to re-design the egg carton. These reuseable modular egg cartons stay in use rather than ending up in the landfill. They are made of a durable composite material consisting of post-consumer plastics and animal feed bags. Further, I wanted to eliminate extra material waste by making the modular carton bottoms part of the egg crate technology for safe transportation.

.png)

CHKN BRAND IDENTITY